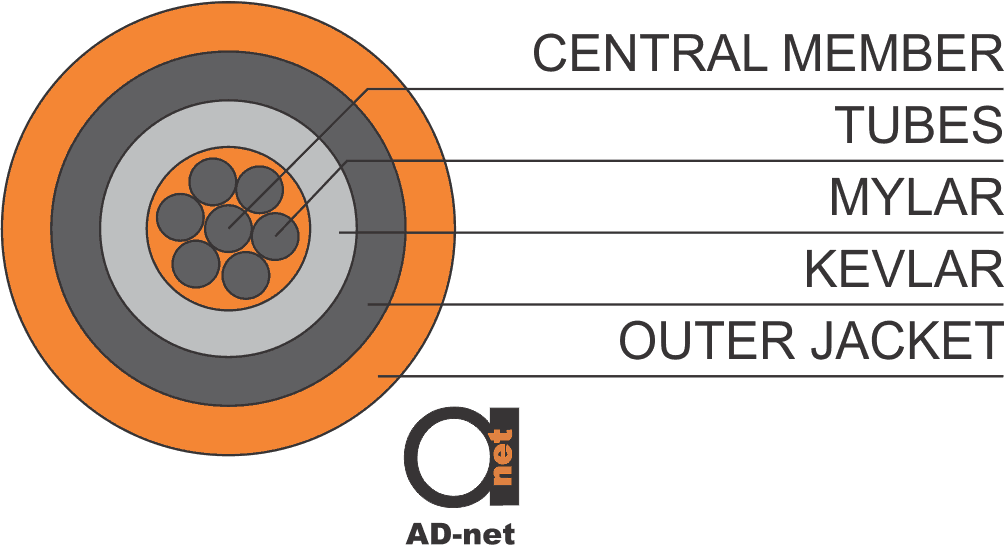

Loose-Tube Cable

As shown in Figure 1, the loose-tube cable is designed modularly and can hold a maximum of 12 fibers per buffer tube (up to 200 fibers per cable fiber count).

These optical fibers are protected and stored in plastic buffer tubes that are color-coded. A gel filling substance prevents water from seeping in. Routine installation and flexibility pressures are bypassed by using additional fiber lengths (relative to the length of the buffer tube).

A dielectric or central steel member offers anti-buckling support. The main tensile strength member for the cable core has an exterior polyethylene jacket extruded over the core.

With regards to armored cables, corrugated steel tape is wrapped over a covered-up cable, and an extra jacket is extruded over the armor. The modular buffer-tube facilitates drop-off fibers easily without interrupting the protected buffer tubes being transferred to other areas.

The design of the loose tube can help identify and administer fibers in the system. Therefore, it is used for OSP installation applications both underground and overhead.

Figure 1 — Loose Tube Design

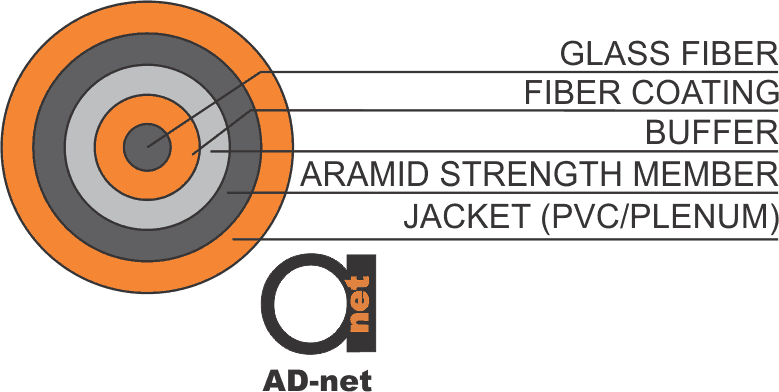

Tightly-Buffered Cable

The fiber in this rugged cable design makes direct contact with the buffering material. This presents a cable structure that keeps each fiber protected while routing, handling, and dropping connections.

Strength members are utilized to minimize installation-related tensile pressure on the cable yam. This one-of-a-kind design makes these cables perfect for connecting OSP cables to terminal equipment, as well as for connecting several communication devices within the same premises.

The tightly buffered cable is illustrated in figure 2.

Figure 2 — Tightly Buffered Cable

Besides the cables already mentioned, there is also an option to use multi-fiber cables. These cable types are developed with strength members that can resist bending and crushing forces during the installation of cable. The exterior cable jackets are OFNP (plenum rated), OFNR (riser rated), or LSZH (low-smoke, zero-halogen rated).

The next blog posts will address these specifications.

These multi-fiber, tightly-buffered cables are renowned for their handling and routing flexibility. Besides the cable types mentioned earlier, there is also the option to use ribbon cables. These are typically used for datacenter applications and ISPs (Internet Service Providers). Each cable is comprised of a flat ribbon-like structure, facilitating additional cable concentration and space.

Fiber Optical Cable – Safety Standards

The NFPA (National Fire Protection Association) in the U.S. is responsible for producing and maintaining minimum requirements and standards for fire prevention and suppression activities.

This is comprised of things like building codes and personal protective equipment used for firefighting operations. For over a century, UL (Underwriters Laboratories Inc.) – a third-party product safety certification organization – has been assessing products and developing Standards for Safety.

UL tests fittings and raceways for nonconductive optical fiber cable installation in accordance with established standards and procedures. UL 2024 is the fundamental standard used to classify FOC raceways, “Optical Fiber Cable Raceway”, as listed in the following table.

| Safety Standards |

| OFC – Optical Fiber, Conductive |

| OFN – Optical Fiber, Nonconductive |

| OFC – Optical Fiber, Conductive, General Use |

| OFNG – Optical Fiber, Nonconductive, General Use |

| OFCP – Optical Fiber, Conductive, Plenum |

| OFNG – Optical Fiber, Nonconductive, Plenum |

| OFCR – Optical Fiber, Conductive, Riser |

You can read more on structure on optics cable and some more information on tight and loose tube cables in this article.