Dimensions of an optical fiber

The width and length of an optical fiber are actually very important as it controls the numerous loss effects that influence the transmission of light waves passing through the fiber.

A bigger center facilitates an elevated combination of light transmitted from the source to the fiber. However, this phenomenon may likely cause saturation issues when received.

The most usual dimensions are shown in the format:

“X” depicts core’s diameter and the “Y” shows cladding diameter.

Here is an example:

40/160 shows a 6 micron core diameter whereas cladding diameter is 160 microns.

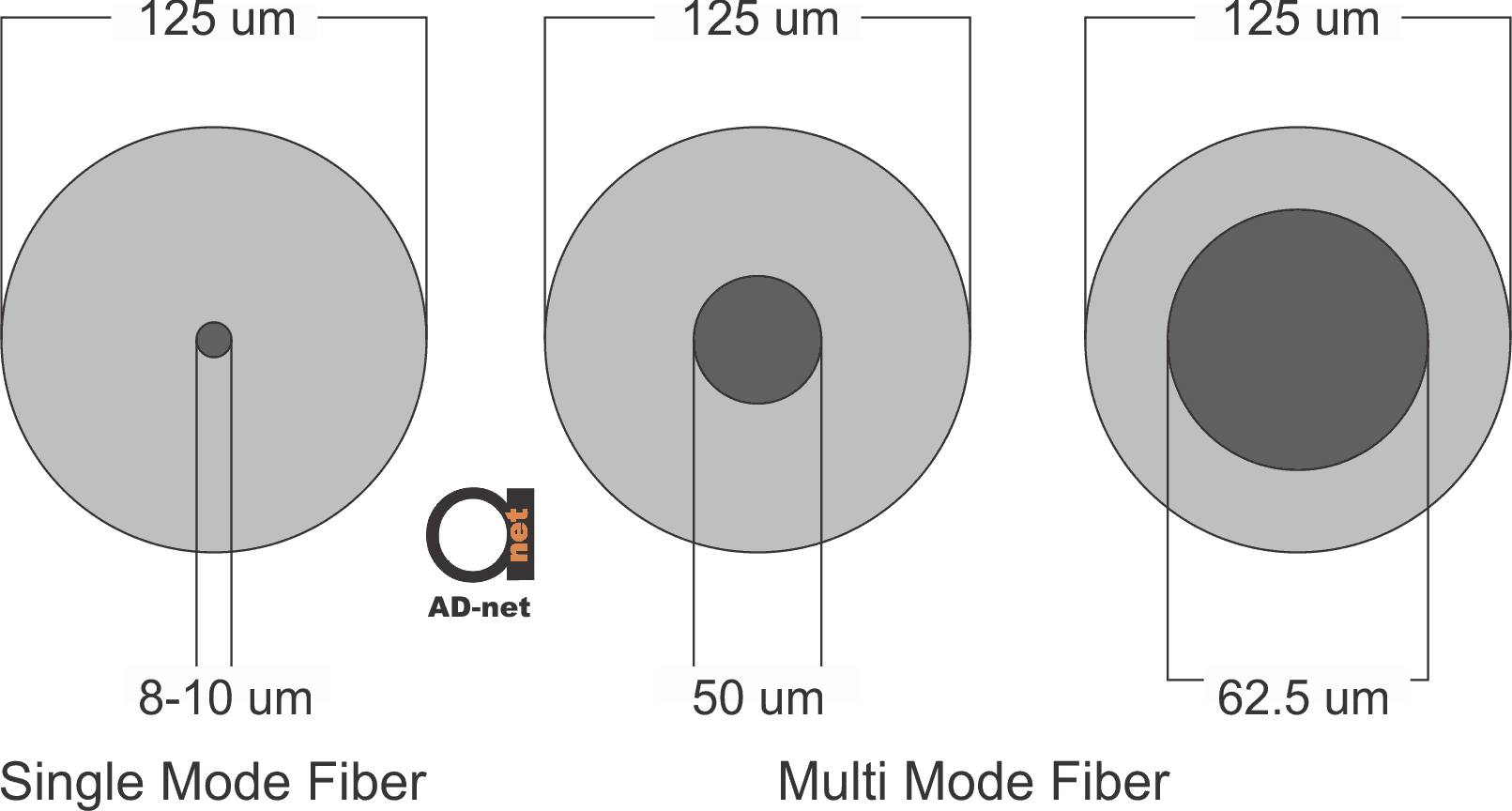

The most typical dimension of a single mode fiber is 8/125 whereas a multimode fiber’s dimensions reach 62.5/125. These are the standard dimensions globally which ensure a great compatibility between connecting devices and supplementary devices.

These global dimension standards of all communication platforms as well as allied interfaces are a vital factor for communication globally. The standard for the external cladding diameter is single mode fibers made of glass material is 125 µm (microns) and for coating it is 245 µm. Single mode fibers have tiny core dimensions which fall into the range of 8 to 10 µm in diameter size.

On the other hand, multimode fiber’s diameter ranges anywhere from 50 to 62.5 as shown in the Figure 1.

Figure 1: Single and Multimode fiber cross-section drawing

Strength

Normal glass suited for home purposes is normally prone to breakage. On the contrary, an optical fiber is greatly durable and possesses a high material strength which covers 600+ in excess per inch.

Still small issues like gaps or cracks may be present upon the manufacturing stage. For this reason, numerous load tests are performed in order to make sure that the strength is intact.

Life Expectancy

Provided the Optical fibers are installed properly and certain procedures are followed, they can last for many years and almost a lifetime. Multiple tests and improvements are performed to increase the duration of fiber installations. Our company offers a wide plethora of tests and trial services available by service providers.

Bending Diameter

A great attribute of optical fibers is that its lightweight construction and size make the installation and flexibility of the optical fiber much easier. However, it is important to take all the necessary measures to make sure there is no tight bending as it may lead to losses of light rays that transmit through the fiber. Bending like this may also leave the optical fiber prone to breakage. Typical testing and skills ensures that the majority of optical fibers can hold a blending diameter of 2-3 inches.

Still, it is recommended that extra intensive care is taken in order to avoid any bending. At the same time, supplementary units like splice trays, or racks and fiber risers can be used to lower the risk of bend losses.