Punch-down blocks equipment started as part of telephone system cross-connect device in the 90s. 66-punch-down block supports 50 pairs of wires, Punch-down tool is necessary to connect wire to the terminal of that block. When “punched down” wires insulation is pierced by metal piece, establishing connection. Two wires can be interconnected using jumpers. Jumpers can be easily changed and replaced, allowing quick and convenient way to reconfigure equipment. Connected wires are usually stationary and are not changed or replaced.

later on 110-punch-down blocks were introduced, which were more adapted to telecommunication needs. Different size blocks can support from 25 to 500 wire pairs. 24 AWG wire is used for the interconnection between cables in 110-punch-down block.

Another option for horizontal cabling termination point is the RJ-45 patch panel.

Reconfiguration is done using simple patch cables. Traditionally it would use 110-block connectors in the back, however smaller connector block can be used for smaller projects.

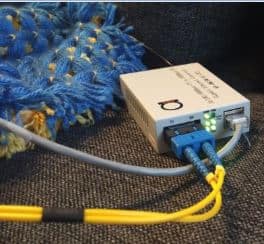

When organizing network that rely on fiber optics cable, fiber-optic connector panel should be used. It is a box containing space for cable slack.

When deploying network it is important to remember to label every cable, every connector when possible using color-coding scheme standard. Additionally, one should group cables of related wires with plastic tie-wraps. However make sure wrapping is not too tight, since it could damage cable structure.